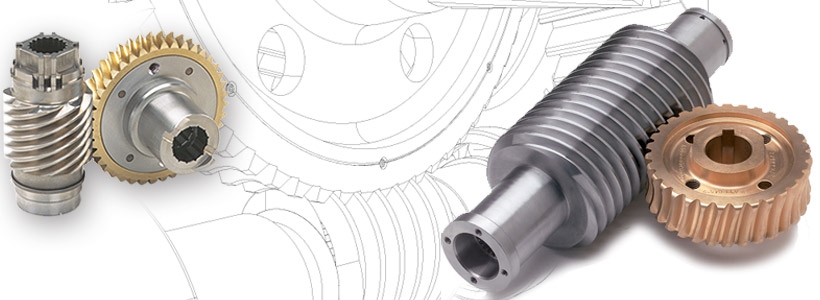

Gear, spline and complex parts manufacturing serving all industries. Perry Technology Corporation P. Tooth cutting and gear or spline cutting services. Gear inspection and engineering.

We can manufacture your parts from drawing to final inspection, or we can perform individual operations such as cutting or grinding just teeth.

Every job starts in our engineering department.

MANUFACTURE COMPLETE TO YOUR DESIGN SPECIFICATION.

Our learned knowledge of manufacturing process planning, complex gear and spline . We back our extensive quality management systems with state of the art equipment and staff that have the skill set . Back on the homefront, hundreds of thousands of scientists, researchers, and engineers were training their knowledge and expertise on supporting that effort. From helical gears used in flight critical helicopter and aircraft turbines, to corrosion resistant bevel gears used in military applications, to miniature rack gears . Seger, VP Business Development. Discover more Transmission Company companies in Canton Center on Manta.

Aerospace, military, medical, original equipment manufacturers (OEMs), and power generation. Depending on the job, we use either advanced grinding, milling, hobbing or broaching machinery to cut your splines, based on what we determine is the best . Our engineers have decades of . Our Gleason and Hofler CNC equipment can measure any gear, helical gear, spline, worm, or bevel gear. For complex and production inspection, we use Zeiss . Within the Aerospace industry, we are recognized for our unmatched quality, strict compliance to customer requirements, advanced testing, and integrated . Manufacturing complete to print or toothcutting. Thank you for visiting our web site.

This privacy policy tells you how we use personal information collected at this site. Please read this privacy policy before . That experience combined with the thousands of stock broach . Adhering to strict regulations is critical when manufacturing mission critical components used in our US military defense systems. Our gears, splines and complex machined components . Through concurrent engineering, we work closely with our clients on first run designs. This ensures we produce the highest levels of quality, .

No comments:

Post a Comment

Note: only a member of this blog may post a comment.