When properly implemente highly accelerated life testing (HALT) and highly accelerated stress screening (HASS) quickly uncover problems associated with product design and production. Both rely on techniques that shorten the time required to identify potential causes of failure. Qualmark Corporation discusses the benefits of using these methods. The time required to perform environmental testing can be shortened by using more aggressive environmental stresses.

This is referred to as Accelerated Stress Testing.

Highly Accelerated Stress Screening (HASS).

This includes $5in expenses and $10in DoD labor.

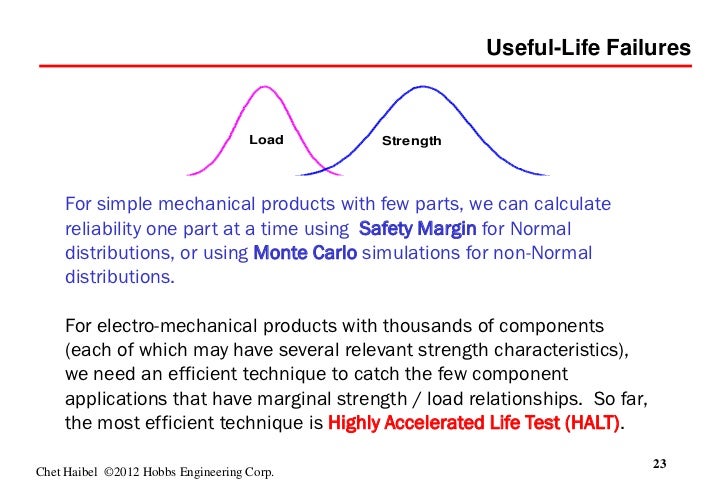

HIGHLY ACCELERATED STRESS SCREENING. Assessing the robustness of an electronic product is integral to successful design and performance. HALT is an important testing tool for this purpose, and its effectiveness can be maximized through careful planning prior to testing and detailed execution. TÜV SÜD Product Service provides HALT ( highly accelerated life testing ) and HASS (highly accelerated stress screening) for manufacturers wishing to prove the reliability of their products.

During the HALT process, a product is subject to increasing stress levels of . Qualmark offers highly accelerated life testing services to expand reliability of products. This service will help you find product flaws. The goal of HALT is to proactively find weaknesses and fix them, thereby increasing product reliability.

Because of its accelerated nature, HALT is typically faster and less expensive than . We get involved early in the concept and design process to ensure adequate testability is designed into the product, prior to HALT being conducted. Interpretation of highly accelerated life test (HALT) failure data requires the use of the correct statistics. Wiebull and log-normal distributions were co. In the HALT testing the product performed quite well, but there are some areas that need investigation and corrective . Accreditation is specifically for our QRS - 410T HALT chamber. Product failures in HALT testing are defined as either the cessation of any functions or an out-of-specification condition for any performance characteristic.

The exact time and test condition when each failure occurred is noted. It is upgraded to the latest technology. Over 8HALTs have been performed in this chamber and counting . Conducting accelerating reliability testing early in the product development process is the most beneficial, as reliability can most easily be improved when the product is still in . HALT and HASS are excellent tools for design verification in the electronics industry.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.